Air Fryers Circuit Safety Protection Solutions and Products from SETsafe | SETfuse

Overview

An air fryer is a kitchen appliance that uses high-speed hot air circulation for cooking. It simulates the effect of deep frying to produce food that is crispy on the outside and tender on the inside, while significantly reducing oil usage to meet healthy eating demands. Its key features include healthy, low-oil cooking, multi-functional capabilities (frying, roasting, baking, etc.), high efficiency, easy cleaning, smart operation, and high safety.

In 2024, the global air fryer market was valued at approximately $1.204 billion, with the Chinese market at around 4.6 billion RMB. The market is projected to continue growing in 2025. By 2030, the global market size is expected to reach $1.884 billion with a Compound Annual Growth Rate (CAGR) of about 6.7%, and the Chinese market is poised to exceed 5 billion RMB, driven by healthy eating trends and the advancement of smart technologies (data sourced from the internet, for reference only).

The Necessity and Standard Requirements for Circuit Protection Components in Air Fryers

Why Use Circuit Protection Components

As a high-power household appliance, an air fryer operates at high temperatures (typically 150°C-200°C) and high power (800W-2000W). This creates several potential circuit safety risks, including overheating, overload, short circuits, and voltage fluctuations. These risks can lead to equipment damage, user injury, or fire. Circuit protection components such as Thermal-Links, fuses, and overload protectors serve the following functions in an air fryer:

Overheating Protection:

Prevents the heating element or circuit board from overheating due to a fan failure or blocked vents, which could cause a fire or component burnout.

Overload/Short Circuit Protection:

Limits excessive current or short circuits to protect the circuit and its components, preventing equipment damage or the risk of electric shock.

Abnormal Voltage Protection:

Absorbs voltage surges to protect the control circuit board from overvoltage shock.

Enhanced Safety & Lifespan:

By cutting off abnormal circuits in a timely manner, these components reduce safety risks and extend the equipment's service life.

National and International Standard Requirements

The circuit protection design of air fryers must comply with national and international safety standards to ensure product safety and market access. The following are some relevant mandatory standards:

Chinese National Standards:

GB/T 40978—2021:

Requires the air fryer to be equipped with an over-temperature protection device (e.g., a Thermal-Link) to cut off the power supply in case of abnormally high temperatures (such as a fan failure), thus preventing fire.

GB 4706.1-2005:

Mandates over-temperature and overload protection for air fryers. Circuit protection components must pass high-temperature, short circuit, and other tests.

CCC Certification:

Air fryers fall under China's Compulsory Product Certification scope and must be equipped with compliant circuit protection devices to be legally sold.

International Standards:

IEC 60335-2-9:

Requires that circuit protection components (e.g., a Thermal-Link) rapidly cut off power in the event of abnormal operation (such as a heating element failure).

UL 1026 (USA):

Requires air fryers to have over-temperature and overload protection. Protection components must pass high-temperature and short-circuit tests.

CE Certification (EU):

Appliances entering the EU market must comply with the Low Voltage Directive (LVD) and Electromagnetic Compatibility Directive (EMC), which mandate the use of circuit protection devices to ensure safety under abnormal electrical conditions.

Mandatory Requirements:

Both Chinese CCC certification and international IEC, UL, and CE certifications require air fryers to be equipped with circuit protection devices (such as Thermal-Links and fuses) to ensure safety and market compliance.

Due to their high-temperature and high-power operation, air fryers require circuit protection components to guard against overheating, overload, and short-circuit risks, ensuring the safety of both the user and the device. National and international standards (e.g., GB/T 40978, IEC 60335, UL 1026) mandate the use of reliable protection devices. Air fryers that comply with these standards can be legally sold, ensuring both safety and market competitiveness.

The Necessity of Single-Use Thermal-Links and Their Circuit Protection Mechanism in Air Fryers

Why Use a Single-Use Thermal-Link for Circuit Protection?

As a high-power (800W-2000W), high-temperature (150°C-200°C) household appliance, an air fryer's heating element and hot air circulation system generate a significant amount of heat during operation. In the event of a fan stall, poor heat dissipation, a circuit fault, or user misuse (e.g., blocking the vents), the internal temperature can rise abnormally, posing a risk of fire, component burnout, or user injury.

A single-use Thermal-Link (Thermal Fuse) is a non-resettable thermal protection device specifically designed to handle extreme overheating situations. Unlike resettable protection devices (like thermistors), a single-use Thermal-Link permanently cuts off the circuit when the temperature exceeds a safety threshold. This ensures the device completely shuts down, preventing potential hazards from being masked by a temporary temperature drop, thereby providing a higher level of safety and reliability. Its primary functions include:

Overheating Protection:

When the device's internal temperature exceeds a preset safe value (e.g., 150°C-200°C, depending on the model), the fuse melts, cutting off the power supply to prevent fire or component damage.

Complete Power Cut-Off:

Once melted, the circuit cannot be restored. This forces the device to stop operation, prompting the user or a service technician to inspect and resolve the issue, preventing the hazard from persisting.

Enhanced Safety:

Protects the user from risks like burns, fire, or electric shock caused by overheating, while also safeguarding key components like the circuit board and heating element to extend the device's lifespan.

Circuits and Components in Air Fryers That May Use Disposable Thermal-Link Fuses for Over-Temperature Protection (For Reference Only)

| Heating Element

| Motor and Fan System

| Control Circuit Board

| Power Input Section

| Thermostat Periphery

| Housing or Structural Components

Installation of Single-Use Thermal-Links in an Air Fryer Circuit

(For reference only; subject to the manufacturer's design)

Installation Location:

A Thermal-Link is typically installed near high-temperature areas to accurately sense overheating. Common locations include:

Close to the heating element (e.g., the heating tube) to monitor its operating temperature.

Near the hot air circulation system (e.g., near the fan) to detect the temperature of the circulating hot air.

Near the control circuit board to protect the main control unit from high temperatures.

Circuit Connection Method:

Series Connection, Physical Fixation

A Thermal-Link is typically connected in series with the power or heating circuit to ensure it can cut off the critical power path when overheating occurs. The device is fixed in place using physical mounting.

Operating Principle:

A Thermal-Link contains a low-melting-point alloy or a heat-sensitive material. When the temperature reaches a preset threshold, the alloy melts or the material breaks, permanently opening the circuit. The fusing process typically takes place in seconds, ensuring a rapid response that cuts off power before the overheating situation can worsen. Once the fuse has blown, the device completely stops working and requires a new Thermal-Link to be replaced before it can be used again.

The use of a single-use Thermal-Link for circuit protection in air fryers provides a reliable and complete safety guarantee against overheating, preventing fire, equipment damage, or user injury. By permanently cutting off the circuit, it ensures that abnormal high temperatures are not overlooked due to temporary cooling. A Thermal-Link is typically installed in series between the power source and the heating element or control board, in a high-temperature area (such as the heating tube or hot air system). Its rapid fusing mechanism relies on a low-melting-point alloy to cut off the power. This design meets the safety needs of high-power, high-temperature air fryers and is a crucial measure for ensuring device safety and earning user trust.

SETsafe | SETfuse Solutions & Products

Protection Type: Over-Temperature Protection

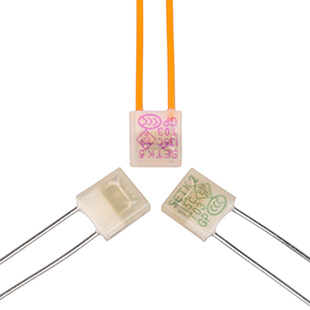

Product Name:

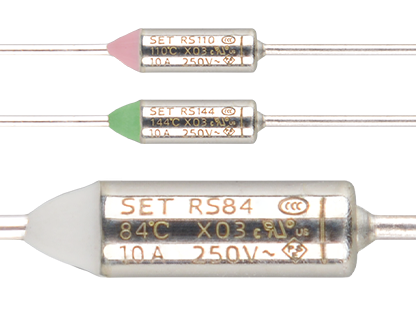

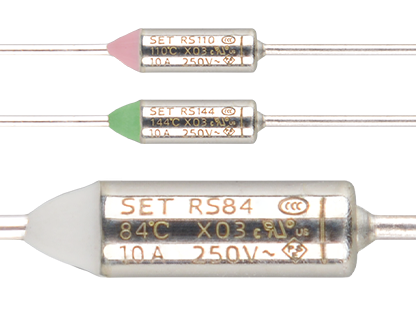

Thermal-Link (Organic Type OTCO)

Series:

Axial Lead Type RS Learn more

Axial Lead Type RT Learn more

Product Name:

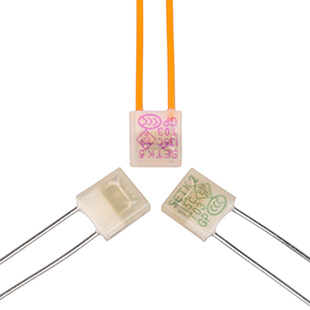

Thermal-Link (Alloy Type ATCO)

Series:

Radial Lead Type K Learn more

Radial Lead Type X Learn more

Radial Lead Type Y Learn more

Radial Lead Type S Learn more

Axial Lead Type H Learn more

Axial Lead Type V Learn more

Why Choose SETsafe | SETfuse Thermal-Links

| Product Manufacturing: Fully Automated Intelligent Manufacturing.

| Complete Specifications: Maximum Rated Current Up to 30 A.

| Guaranteed Quality: Product Functionality, Performance, and Reliability are Verified.

15 More items than national standards: 30 reliability test items, Including Mechanical, Electrical, Temperature, Soldering, Environmental, and Life Tests.

41.67 Times Higher Than National Standards: Holding Temperature Test Duration is 1,000 hours (National Standard: 24 hours).

2.5 Times Higher Than National Standards: Operating Temperature Accuracy is ±2°C (National Standard: 0/-10°C).

| Multi-System Certifications: Learn more

| Environmentally Friendly Products: HSF (Compliant with RoHS 3.0, REACH, Halogen-Free) Learn more

| Diverse Industry Applications: Learn more

Company Expertise

| Over 25 years of professional design, manufacturing, and sales of circuit protection components. Our products are sold in over 40 countries, and many Fortune 500 companies choose SETsafe | SETfuse. Learn more

Guaranteed, Worry-Free Service

| Pre-sales, in-sales, and after-sales support with professional personnel (feedback within 1 hour) Learn more

Other Circuit Protection Components Used in Air Fryers

In addition to the single-use Thermal-Link, air fryers often use other circuit protection components to counter risks associated with high power (800W-2000W) and high temperatures (150°C-200°C). Each component plays a unique role in addressing specific risks:

Fuse

Function:

Overload Protection:

When the circuit current exceeds its rated value (due to an excessive load or a short circuit), the metal wire inside the fuse melts, cutting off the circuit and preventing wire overheating or fire.

Short Circuit Protection:

Rapidly disconnects the circuit during a short, protecting internal components (e.g., the control board, motor) from high current surges.

Typical Application:

Installed at the power input or in the main circuit as the first line of current protection.

Varistor

Function:

Over-voltage Protection:

Absorbs power voltage surges (e.g., transient high voltages from lightning strikes or grid fluctuations), protecting the circuit board and sensitive electronic components from over-voltage damage.

Surge Suppression:

Reduces voltage spikes to protect components like motors and control chips, extending the device's lifespan.

Typical Application: Installed at the power input, near the power cord or the circuit board's input port.

...

Summary

In addition to a single-use Thermal-Link (for extreme over-temperature protection), air fryers also commonly use fuses (for overload/short-circuit protection), thermistors (for temperature monitoring and dynamic control), varistors (for over-voltage protection), overload protectors (for dynamic overload protection), circuit breakers (for overload/short-circuit protection in high-end models), and EMI filters (for electromagnetic compatibility). These components provide multi-level protection against various circuit risks (e.g., overheating, overload, short circuits, over-voltage, electromagnetic interference), ensuring the device's safe and stable operation while extending its service life. Grounding protection, as a fundamental safety measure, further reduces the risk of electrical leakage. Together, these components form a comprehensive circuit protection system for air fryers that complies with mandatory national and international safety standards (e.g., GB 4706.1, IEC 60335, UL 1026).

Partner with SETsafe | SETfuse to Transform Technical Challenges into Reliable Solutions

When you encounter technical challenges in selecting circuit protection components or designing system solutions, the professional engineering team at SETsafe | SETfuse is your trusted partner. Specializing in over-temperature, over-current, over-voltage, and active protection technologies, SETsafe | SETfuse offers comprehensive technical expertise and rapid response to meet your needs. Whether you require precise product parameter guidance or comprehensive system-level protection solutions, SETsafe | SETfuse delivers professional, practical, and efficient recommendations and support.

From initial design consultation and solution implementation to post-sales product assurance, we provide end-to-end collaboration, ensuring your project progresses seamlessly and reliably. For any inquiries or requirements, please contact us at: sales@SETfuse.com

Professional Circuit Protection, Supporting You from Concept to Production

Rechargeable Battery

Rechargeable Battery Lithium Battery Thermal Runaway

Lithium Battery Thermal Runaway Electric Power Tool

Electric Power Tool New Energy

New Energy PV Power Generation

PV Power Generation Wind Power Generation

Wind Power Generation Energy Storage Batteries

Energy Storage Batteries Energy Storage System (ESS)

Energy Storage System (ESS) Electric Vehicles

Electric Vehicles EV Charging Stations

EV Charging Stations Light Electric Vehicles

Light Electric Vehicles Home Appliances

Home Appliances Small Household Appliances

Small Household Appliances Large Home Appliance

Large Home Appliance Home Appliance Component

Home Appliance Component Kitchen Appliances (Hotplates ...)

Kitchen Appliances (Hotplates ...) Air Fryer

Air Fryer Coffee Machine

Coffee Machine Electric Iron

Electric Iron Smart Toilet

Smart Toilet Personal Digital Products

Personal Digital Products Lifestyle Appliances

Lifestyle Appliances Office Equipment

Office Equipment Walkie Talkie

Walkie Talkie Medical Analysis Instrument

Medical Analysis Instrument Medical Auxiliary Facility

Medical Auxiliary Facility Medical Instrument

Medical Instrument Lighting

Lighting Indoor Lighting

Indoor Lighting Outdoor Streetlight

Outdoor Streetlight Power Supply

Power Supply Power Supply (Power < 20 Watts)

Power Supply (Power < 20 Watts) HVDC in Data Centers

HVDC in Data Centers Power Supply Unit (PSU)

Power Supply Unit (PSU) Battery Backup Unit (BBU)

Battery Backup Unit (BBU) Uninterruptible Power Supply (UPS)

Uninterruptible Power Supply (UPS) Telecommunication

Telecommunication Automotive

Automotive Power Strip

Power Strip Surge Protection Power Strip

Surge Protection Power Strip Security & Protection

Security & Protection Tethered Drone

Tethered Drone Industrial Robot

Industrial Robot Humanoid Robot

Humanoid Robot Service Robot

Service Robot Specialty Robot

Specialty Robot Agricultural Irrigation Equipment

Agricultural Irrigation Equipment Smart Agricultural Greenhouse

Smart Agricultural Greenhouse Rail Transit Facility

Rail Transit Facility Rail-Vehicle

Rail-Vehicle Railway Power Supply

Railway Power Supply Fuel Dispenser

Fuel Dispenser Traffic Control System

Traffic Control System Traffic Signal Light

Traffic Signal Light Commercial Cleaning Equipment

Commercial Cleaning Equipment Delivery Locker (Drone)

Delivery Locker (Drone) Vending Machine

Vending Machine Lightning Protection Components

Lightning Protection Components HVAC Rooftop Systems

HVAC Rooftop Systems Outdoor Electric Wall Mounted Heater

Outdoor Electric Wall Mounted Heater Flag Explain

Flag Explain