Xiamen SET Electronics Co., Ltd.

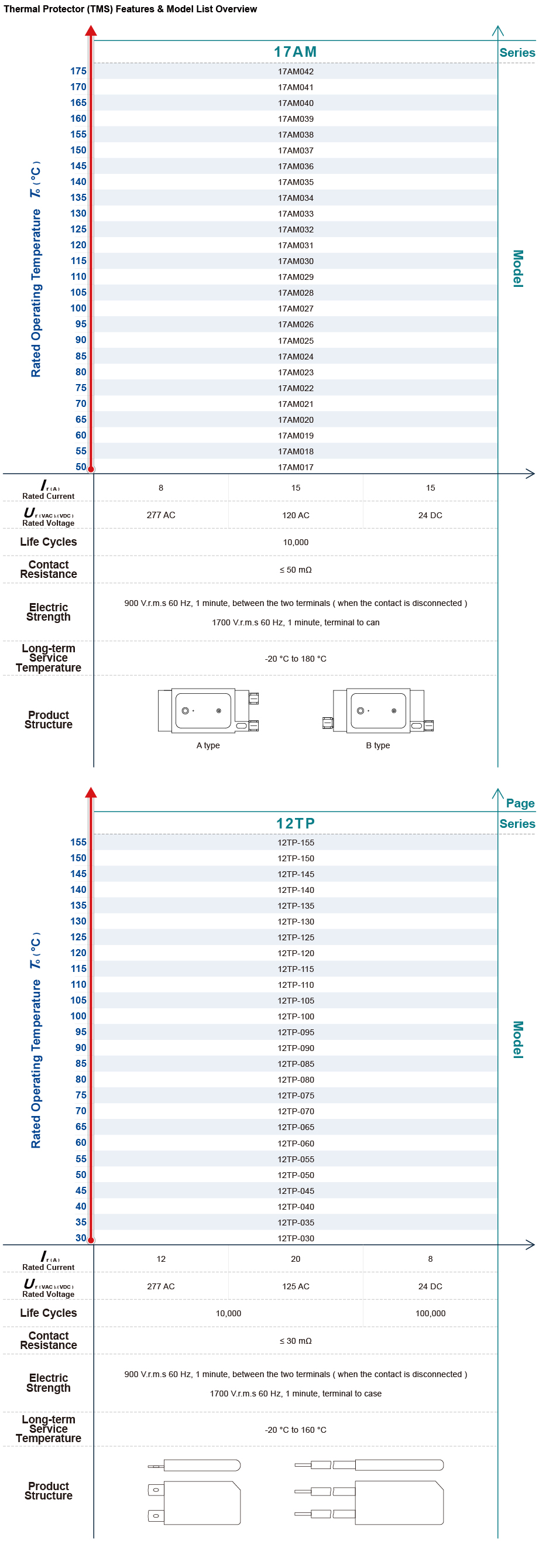

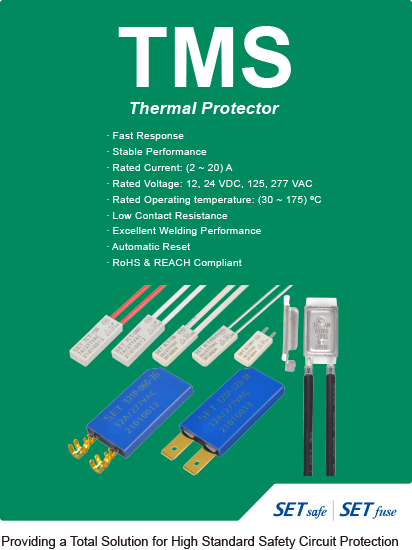

SETsafe | SETfuse thermal protector (TMS) mainly uses bimetal disc to sense current or temperature. When the temperature of the bimetal disc reaches the pre-calibrated temperature, the bimetal disc quickly trips, connect or disconnect the circuit. Ambient temperature increasing or current increasing or both of the above may cause the temperature of the bimetal to reach its pre-calibrated temperature, thereby connect or disconnect the circuit. This device covers rated current from 0 to 20 A, rated operating temperature from 30 °C to 175 °C by various part numbers. It complies with RoHS and REACH environmental protection requirements.

Operating Temperature

The actual temperature at which the thermal protector contacts are closed (normal open) or disconnected (normal closed) .

Recovery Temperature

After the thermal protector contact is closed or disconnected, the contact produces the actual temperature value corresponding to the open (normal open) or closed (normal closed) contact.

Ir

Rated Current

The current used to classify a thermal protector, which is the maximum current that Thermal Protector allows to carry and is able to cut off the circuit safely.

Ur

Rated Voltage

The voltage used to classify a thermal protector, which is the maximum voltage that Thermal Protector allows to carry and is able to cut off the circuit safely.

Cycle Life

The number of periodic changes in the temperature of a bimetal element from its original state to its open (or closed) state.

Delta Temperature

Is the difference between the zero current calibrated opening temperature and ambient temperature at the protector location.

Panel Mount, Through Hole, Surface Mount

Wire, Welding, PCB Mount, QC Terminal, Rivet

● Battery Packs

● Generators

● Transformers

● Heating Appliances

● Power Tools

● Solenoids

● Motors

● Chargers

● Instruments

● PCB

● LED Drivers

● Water Heaters

● Car Electric Heated Seats

● Dryers

● Shaded Pole Motors

● Permanent Split Capacitor Motors

● Fluorescent Lighting Ballasts

● HID Ballasts

● Transformers

● Lighting Equipment

● Vacuum Cleaners

● Automotive Motors

SETsafe | SETfuse Quality Policy

Provide Industry-Leading Products

Raw-materials Supplier

Select critical raw materials: Must be from a manufacturer with quality management system (ISO9001, IATF16949) certification.

Annual or Quarterly Audits.

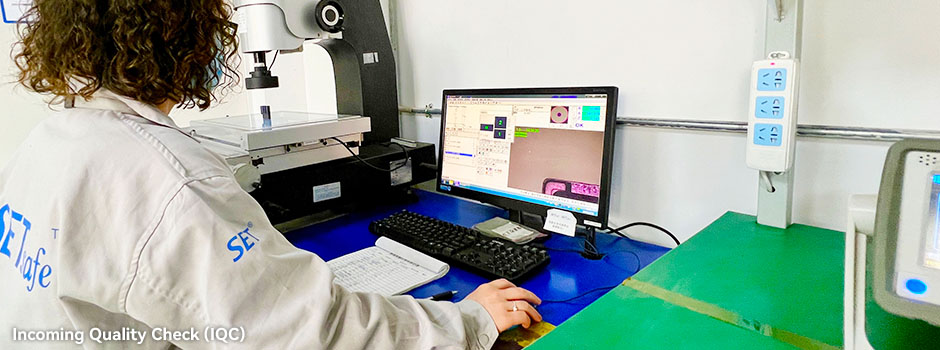

IQC (Incoming Quality Check)

AQL(MIL-STD-105E), Dimensions, Function, Visual Inspection, RoHS & REACH Test.

Document

Formulate corresponding incoming inspection specifications (01-QA-06-xxx) for each key material according to design data such as material technical indicators.

Testing Equipment and Tools

Vernier Calipers, Mircometer, Hardness meter , Micro-resistance tester, Spectrum Analyzer, etc.

Manufacturing Process

Online Inspection and Testing (Function 100% Testing).

Document

Process Flow Chart.

Failure Mode and Effects Analysis (FMEA).

Control Plan (CP).

Standard Inspection Procedure (SIP).

Standard Operating Procedure (SOP).

Online Testing and Inspection

Temperature test system (100% Automatic Testing).

100% Resistance test, 100% Visual inspection.

etc.

IPQC (In Process Quality Control) Inspection

AQL(MIL-STD-105E), Dimensions Inspection, Function Test, Visual Inspection.

FQC ( Final Quality Control)

AQL(MIL-STD-105E), Dimensions Inspection, Function Test, Visual Inspection, RoHS & REACH Test.

Reliability Test

Test specification (01-TE-01-1006-XXX).

Including 31 items of Appearance Requirements, Electrical Performance, Mechanical Performance, Environmental Test and Life Test. e.g.

Tension Test.

Plug Test.

Temperature Characteristics Test.

Insulation Resistance Test.

Electrical Strength Test.

Temperature Impact Test.

Salt Fog Test.

Drop Test

etc.

OQC (Outgoing Quality Control)

AQL(MIL-STD-105E), Packaging, Labeling, Quantity Inspection.

Agency

Agency (Safety Certificate) Annual, Quarterly Audits.

Management System

ISO9001, (TUV approved and issued certificate).

ISO14001, ISO45001, etc.

Click to view the certificate

Environmental

RoHS & REACH Compliant.

SETsafe | SETfuse

Usage

1. These devices are not intended for use as service or repair components, It should be strictly used by Original Equipment Manufacturer.This product is not rated as explosion proof and should not be applied in any application where flammable vapors or dust is present. End of life failure of this device may result in either open or closed circuit condition, and as such, OEMs must apply end of life protection in series, per agency requirements.

2. Users are solely responsible for proper design, application and function of this product in the end product or system. Users must evaluate the suitability of these devices in their application with respect to temperature settings, mechanical and electrical life cycles, electrical loads and environmental conditions.

3. When atmosphere press is from 80 kPa to 106 kPa, the related altitude shall be from 2000 meter to - 500 meter.

Replacement

The product is a non-repairable product. For safety sake, it shall be replaced by an equivalent part and mounted in the same way.

Storage

Do not store the product at high temp., high humility or corrosive gas environment, avoid influencing the solder-ability or contact resistance of the lead wires. The product shall be used up within 1 year after your receiving goods.

Installation Position

1. The product should be as close to the protected parts as possible. For example, in the motor, the product should be embedded in the upper end of the motor stator coil. If the test conditions allow, the field temperature of the motor should be measured to determine the highest temperature point.

2. During the installation of the product, it is forbidden to strike heavily, and the product shall not be extruded at the installation position to avoid deformation of the product shell, which will seriously affect the protection performance of the product.

Warnings

Risk of Material Damage and Hot Enclosure

1. The product’s side panels may be hot, do not touch till cool down.

2. Follow proper mounting instructions including force values. Options failure to follow these instructions can result in serious injury, or equipment damage. Hazard of electric shock, explosion or arch flash.

3. Disconnect all power before installing or using this product.

4. Make sure all the connections and protection measurements before turning on power. Failure to follow these instructions will result in death or serious injury.

Thermal Protector (TMS) Catalog

View PDF

Over Temperature Protection(85)

Over Temperature Protection(85)

Over Voltage Protection(232)

Over Voltage Protection(232)

Over Current Protection(59)

Over Current Protection(59)

Active Protection(18)

Active Protection(18)

Accessories(3)

Accessories(3)